This manual provides essential guidance for understanding, installing, and operating the XG-X Series vision system, focusing on communication protocols, setup, and integration with external devices.

Overview of the XG-X Series Vision System

The XG-X Series Vision System is a customizable, high-performance solution designed for industrial automation and precision tasks. It integrates advanced image processing capabilities with flexible communication protocols, enabling seamless interaction with external devices, controllers, and PLCs. The system supports various vision applications, including alignment, inspection, and data capture, making it versatile for diverse industrial needs. Its modular design allows users to configure and expand functionality according to specific requirements. The XG-X Series is supported by dedicated software tools, such as VisionEditor, which simplifies system configuration and parameter adjustment. With robust communication controls, it ensures efficient data exchange and operational reliability in industrial environments, making it a cornerstone of modern automation systems.

Purpose and Scope of the Communications Control Manual

This manual serves as a comprehensive guide for configuring and managing communication functions of the XG-X Series vision system. It provides detailed procedures for setting up communication protocols, interfacing with external devices, and integrating with industrial controllers. The scope includes troubleshooting common issues, performing diagnostic checks, and ensuring optimal system performance. Users will find instructions for capturing and saving images, adjusting parameters, and customizing settings via PC software. The manual also covers essential maintenance tasks and software updates to keep the system running efficiently. It is designed for both novice and experienced users, offering clear, step-by-step instructions to maximize the functionality of the XG-X Series in various industrial applications.

Installation and Setup of the XG-X Series

The manual outlines hardware installation requirements, connectivity steps, and initial configuration procedures for the XG-X Series, ensuring proper setup and integration with external systems.

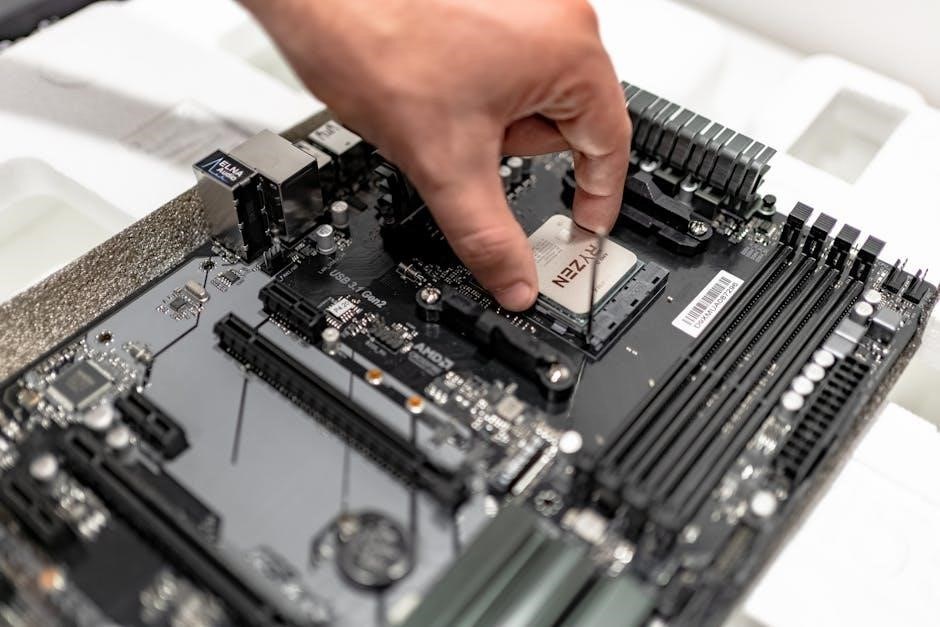

Hardware Installation and Connectivity Requirements

The XG-X Series requires precise hardware installation, including connecting cables, configuring network settings, and ensuring proper power supply. Users must adhere to specified wiring and environmental conditions to maintain optimal performance. The manual provides detailed instructions for mounting the vision system and linking it to external devices, such as PLCs or industrial robots. Proper grounding and power supply configurations are essential to prevent interference and ensure reliable operation. Additionally, the system must be installed in an environment with controlled temperature and humidity levels to avoid damage. Refer to the manual for specific hardware requirements and installation guidelines to ensure a seamless setup process.

Initial Configuration and Startup Procedures

Following hardware installation, the initial configuration involves powering up the system and performing a series of startup checks. Ensure all cables are securely connected and the power supply is stable. Use the VisionEditor software to configure network settings, IP addresses, and communication protocols. Perform a system self-test to verify functionality. Review the controller’s operation methods and ensure compatibility with external devices. Test communication with connected devices, such as PLCs or robots, using predefined control commands. Refer to the manual for specific startup procedures and troubleshooting steps. Complete a final system check to ensure all components are operational before initiating full-scale operation. Proper initialization ensures reliable performance and seamless integration with external systems.

Core Functionality of the Communications Control

The XG-X Series Communications Control enables seamless integration with external devices through predefined protocols and commands, ensuring efficient data exchange and system coordination for industrial automation.

Understanding Communication Protocols and Interfaces

The XG-X Series utilizes standardized communication protocols such as Ethernet/IP and PROFINET to ensure compatibility with industrial automation systems. These protocols enable seamless data exchange between the vision system and external devices like PLCs or robots. The system supports multiple communication interfaces, allowing users to integrate it into diverse industrial environments. Control commands facilitate interactions such as program switching and image capture, while predefined data formats like CSV and XML ensure consistent data handling. VisionEditor software provides tools to configure and monitor communication settings, optimizing integration with external controllers. Real-time communication capabilities enhance synchronization and efficiency in automated workflows, making the XG-X Series adaptable to various industrial applications while maintaining robust performance and reliability.

Interfacing with External Devices and Controllers

The XG-X Series seamlessly interfaces with external devices and controllers, including PLCs and industrial robots, through standardized communication protocols. This ensures compatibility and efficient integration into existing industrial automation systems. The system supports various control commands for operations like program switching, image capture, and data transfer. Predefined communication settings simplify the connection process with devices such as DENSO robot controllers, while the VisionEditor software provides tools for customizing and monitoring interactions. Real-time data exchange enhances workflow synchronization, allowing the XG-X Series to adapt to diverse industrial environments while maintaining high performance and reliability. This capability ensures smooth operation in complex automated systems, making it a versatile solution for advanced vision-guided applications.

Configuration and Adjustment via PC

The XG-X Series allows PC-based configuration and adjustment using VisionEditor software, enabling parameter customization, image capture, and integration with PLCs for enhanced industrial automation control.

Using VisionEditor for System Configuration

VisionEditor is a comprehensive software tool designed for configuring and optimizing the XG-X Series vision system. It allows users to create, edit, and manage inspection programs with precision. The software supports alignment functions, enabling precise calibration and image capture. VisionEditor also facilitates real-time monitoring and adjustments, ensuring accurate communication between the vision system and external devices. It streamlines the integration of the XG-X Series with PLCs and industrial robots, enhancing automation capabilities. The intuitive interface provides access to advanced parameters, enabling customization to meet specific application requirements. VisionEditor is essential for maximizing the performance and efficiency of the XG-X Series in industrial environments, ensuring seamless communication and control. Regular updates and support are available to maintain optimal functionality.

Advanced Parameter Adjustment and Customization

The XG-X Series offers advanced customization options through VisionEditor, allowing users to fine-tune system parameters for optimal performance. This includes adjusting image processing settings, communication protocols, and integration with external controllers. VisionEditor provides detailed access to parameters such as sensitivity, filtering, and timing, enabling precise customization for specific applications. Additionally, users can define custom scripts and commands to enhance functionality. The software supports tailored configurations to meet unique operational needs, ensuring seamless interaction with PLCs and industrial robots. Advanced parameter adjustment is essential for maximizing system efficiency and accuracy in complex industrial environments. Regular updates to VisionEditor ensure compatibility with the latest hardware and software advancements, maintaining peak performance levels.

Data Management and Integration

The XG-X Series enables seamless integration with industrial systems, capturing and saving images/results to PCs. It supports communication with PLCs and robots, ensuring efficient data management and consistency.

Capturing and Saving Images/Results to a PC

The XG-X Series allows users to efficiently capture and save images and inspection results directly to a PC. This functionality is supported by the VisionTerminal software, which enables remote monitoring and data management. The system ensures high-resolution image capture, storing detailed results for analysis and record-keeping. Communication protocols facilitate seamless data transfer, ensuring accuracy and reliability. Users can configure settings to automate image capture and saving processes, enhancing workflow efficiency. This feature is particularly useful for quality control, enabling quick access to inspection data for review and reporting purposes. The system also supports integration with external devices, making it easy to share and archive critical information.

Integration with PLCs and Industrial Robots

The XG-X Series seamlessly integrates with PLCs and industrial robots, enabling advanced automation and control. Communication protocols facilitate data exchange, allowing the vision system to interact with machinery and control systems. Control commands enable functions like program switching and image capture, ensuring synchronized operation. Integration with robots, such as DENSO RC8 controllers, enhances precision in tasks like part detection and alignment. This capability streamlines production processes, improving efficiency and accuracy. Detailed setup procedures and data lists are provided in the manual to ensure smooth integration. By connecting the XG-X Series with industrial systems, users achieve enhanced control and harmonized workflow.

Troubleshooting and Maintenance

The manual provides detailed diagnostic techniques and maintenance schedules to ensure optimal performance. Regular software updates and system checks prevent issues, ensuring reliable operation and longevity.

Common Issues and Diagnostic Techniques

Common issues with the XG-X Series include communication errors, connectivity problems, and software glitches. Diagnosing these often involves checking cable connections, reviewing error logs, and ensuring firmware is updated. Communication errors can arise from mismatched baud rates or incorrect protocol settings, while connectivity issues may stem from faulty wiring or improper network configuration. Software-related problems can often be resolved by restarting the system or reinstalling drivers. The manual provides step-by-step troubleshooting guides, including how to use diagnostic tools like status indicators and system logs to identify root causes. Regular maintenance, such as updating software and cleaning hardware, helps prevent recurring issues, ensuring smooth operation and minimizing downtime.

Scheduled Maintenance and Software Updates

Regular maintenance is crucial for optimal performance of the XG-X Series. Schedule periodic checks of hardware and software to prevent unexpected downtime. Software updates ensure compatibility and fix bugs, while firmware updates enhance functionality and security. Always back up configurations before applying updates. Clean camera lenses and sensors to maintain accuracy. Check cable connections and replace worn-out components promptly. Refer to the manual for detailed update procedures and maintenance schedules. Properly documenting and implementing these routines ensures reliable operation and extends system lifespan. Failure to update may lead to compatibility issues or reduced performance. Plan maintenance during low-activity periods to minimize operational impact.

Advanced Features and Best Practices

The XG-X Series offers advanced alignment functions for precision and optimizing system performance. Best practices include regular software updates and leveraging integration with PLCs for seamless control.

Utilizing Alignment Functions for Precision

The XG-X Series alignment functions enable high-accuracy positioning and calibration, crucial for vision-guided applications. These features utilize advanced algorithms to detect and correct positional deviations, ensuring precise image capture and processing. By integrating alignment functions, users can achieve consistent results in industrial environments, improving overall system reliability. Regular software updates and adherence to best practices further enhance the accuracy and performance of these alignment tools, making them indispensable for demanding automation tasks. Proper setup and configuration, as outlined in the manual, ensure optimal functionality and minimize operational disruptions.

Optimizing System Performance and Efficiency

Optimizing the XG-X Series involves fine-tuning settings in VisionEditor, ensuring efficient communication protocols, and maintaining up-to-date software. Regularly reviewing and adjusting parameters enhances processing speed and accuracy. Properly managing data flow and minimizing unnecessary tasks reduces system load. Implementing best practices, such as scheduled maintenance and optimizing power supply, ensures reliable operation. Efficient integration with external devices and controllers further boosts performance. By following the manual’s guidelines, users can maximize the system’s potential, ensuring smooth and efficient functionality in industrial applications. These optimizations are critical for maintaining peak productivity and minimizing downtime in automated environments.